QUALITY

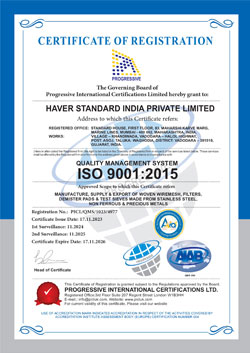

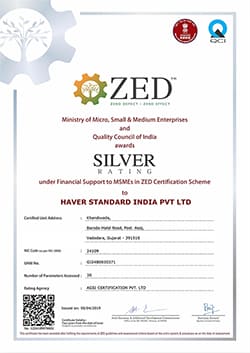

Being part of the Haver Group, Germany, for over 20 years and being ISO certified since 1996, one of the most important criteria at HAST is the quality of material produced.

We work on the PDCA (Plan - Do - Check - Act) approach which works as an analysis and control method for the suggestions and implementations from our Quality Team.

Quality for us is a process in which each employee and supplier plays a significant role. This is an essential state-of-mind for each person involved which is instilled from the top management. We strongly believe that suggestions to steer clear of mistakes are on top priority followed by an immediate solution to avoid repetition. All our quality processes are documented for future reference.

We would be more than happy to have your personnel deputed to our organization to inspect our work and personally see the quality we maintain.

Our products are manufactured in a special temperature controlled environment with a special epoxy flooring to avoid any dust particles or toxic materials into our end product.

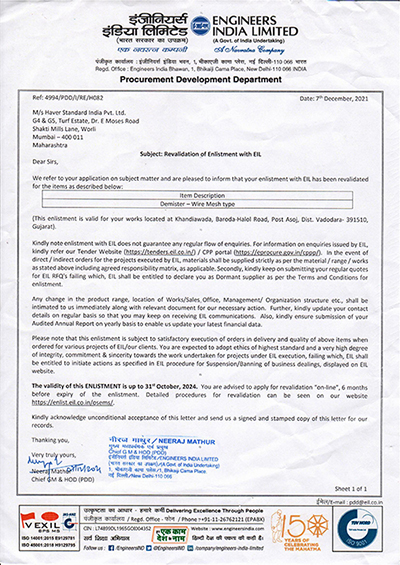

These are some of the third party inspection agencies used by our customers. We shall be happy to share their local details based on your requirement.

- ● HAST is committed to building a quality organization with our customers as our primary focus

- ● We shall achieve this through a process of continual improvement in all areas of operations, giving emphasis on people's active involvement, adherence to documented procedures and continuous up-gradation of technology

- ● HAST is committed to comply with requirements and constantly improve the effectiveness of the quality management system, providing a framework for establishing and reviewing quality objectives.